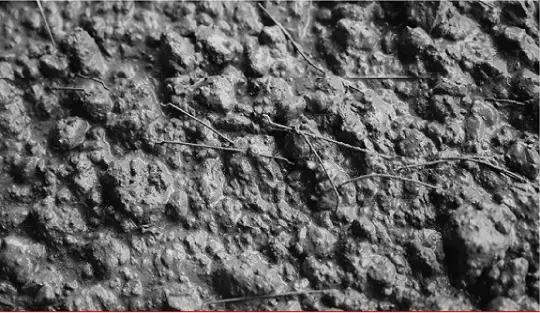

In demanding industrial environments, flooring is more than just a surface — it is a foundation that supports heavy loads, nonstop movement, and constant pressure. But traditional concrete floors, filled with joints, often become weak over time. These joints crack, break, and collect dust, creating long term problems that affect both safety and efficiency.

Jointless industrial flooring is designed to eliminate those problems from the start. By reducing the number of construction joints, it offers a smoother, stronger surface that performs better and lasts longer.

If your facility needs a reliable floor that can keep up with your operations without frequent repairs, jointless flooring is a practical and proven choice.

Why Cracks and Joints Cause Trouble

In most industrial floors, joints are placed to help control cracks. But in busy spaces, those joints often become weak points.

- Cracks begin near joints and spread

- Forklifts and carts bump or shake at each joint

- Joint edges break, creating uneven surfaces

- Dust collects where the joints fail

- Regular patching or filling is needed to keep the floor safe

These issues do not just affect the surface. They also reduce productivity, wear down equipment faster, and can lead to safety risks for workers moving through the space every day.

In high traffic zones, this repeated damage at the joints becomes a never-ending cycle of repair and disruption.

How Jointless Floors Solve These Problems

Jointless flooring changes the game by removing most of the weak spots that cause cracking and damage in traditional floors. It is poured in large, reinforced sections with fewer construction joints, making the surface stronger and more stable over time.

One reason this system works so well is the use of steel fiber reinforcement. These fibers are blended directly into the concrete mix, helping the entire slab hold together under pressure. They reduce internal stress and control the tiny cracks that usually grow into larger problems, especially in areas with heavy loads or high movement.

With this design, jointless floors offer many long term advantages:

- Fewer Cracks

The floor holds together better and resists cracking, even under constant vehicle traffic, shifting loads, or vibration from equipment. - Low Maintenance

Because the surface stays intact and edges do not break down, there is less need for repairs. This means operations can continue without frequent interruptions. - Smooth Movement

Vehicles like forklifts roll more easily across the surface without bumping over joints. This helps improve efficiency and reduces equipment wear. - Cleaner Surface

Fewer joints means fewer places for dust and debris to collect. The result is a neater work environment that is easier to clean and maintain.

Longer Lasting Performance

The floor is built to handle pressure and heavy use over time. It stays reliable for years with fewer surface failures, making it ideal for busy industrial operations.

Where Jointless Flooring Is a Smart Choice

Jointless floors are ideal for places where floors need to work hard every day:

- Warehouses and storage facilities

- Logistics and sorting centers

- Manufacturing units and assembly lines

- Cold storage and freezer rooms

- Food and pharma units that need clean environments

In these environments, a damaged floor slows everything down. A jointless solution helps the business run smoothly and creates a safer, cleaner workspace for everyone.

Explore our Jointless Flooring Services

Conclusion

Jointless industrial flooring helps you avoid the usual problems that come with cracks and joint failures. It gives you a surface that is strong, smooth, and easy to maintain — even under heavy use.

It is more than just a concrete slab. It is an upgrade that saves time, protects your equipment, and gives your operations the strong foundation they need.

If your team is constantly fixing floor issues, it is time for a better solution. Jointless floors take away the stress of maintenance and bring back control, safety, and confidence to your workspace.

Want to stop worrying about floor repairs

Get in touch with us to learn how jointless flooring can help your business stay focused on what matters.